Award Nomination:

Shoreham Port has been operating as a Trust port for over 260 years. Our purpose remains to continually ‘improve our port for everyone’. First and foremost, this means everyone getting home safe and well daily. This is the primary objective of our Masterplan, a simple eight-point plan which everyone is involved in creating.

One of our areas of highest risk is our landside operations. A team of 40 Port Operatives are responsible for the safe and efficient discharge of around 150 vessels a year. Following discharge, the team then load imported timber onto over 12,000 lorries, ready for its onward distribution. Whilst most timber packs can be loaded with dunnage attached, occasionally this has to be adjusted or supplemented, requiring our colleagues to work at height as the HGV is loaded.

Wherever possible we aim to eliminate risk from our operations and therefore we wanted to identify a method of achieving correctly placed dunnage without the need to work at height. Our small team set to work, designing and testing several prototypes before creating an innovative solution – the ‘dunnage placement tool’.

It’s been quite a journey, with high collaboration and engagement with colleagues at all levels, which has led us to a finished product which has completely eliminated working at height while lorry loading, making our team substantially safer. It’s one of a kind, and we believe it could make many more front-line workers across the wider Port sector safer.

Additional Information

Falls from height are the most common cause of fatal injuries to workers (HSE, 2023) and are currently the fourth greatest source of non-fatal injury (HSE 2022/23). We have had first-hand experience of the life changing impact they can have within the Port, which further motivates us to constantly review our practices to see how we can fulfil our commitment to everyone getting home safe and well daily.

In a proactive review of our lorry loading process, noting that elimination – physically removing a hazard, is the most effective way to reduce a risk, we set to work finding a way to remove the requirement to work from height.

We designed the ‘dunnage placement tool’, a piece of equipment that holds dunnage at exactly the right angle, at the end of a lightweight pole, thus enabling an Operative to stand on the ground close to a lorry and position the dunnage exactly where it is needed, with precision, ease, and avoiding the need to work at height. The tool also holds a sufficient portion of the dunnage to prevent it from accidentally falling out and striking anyone.

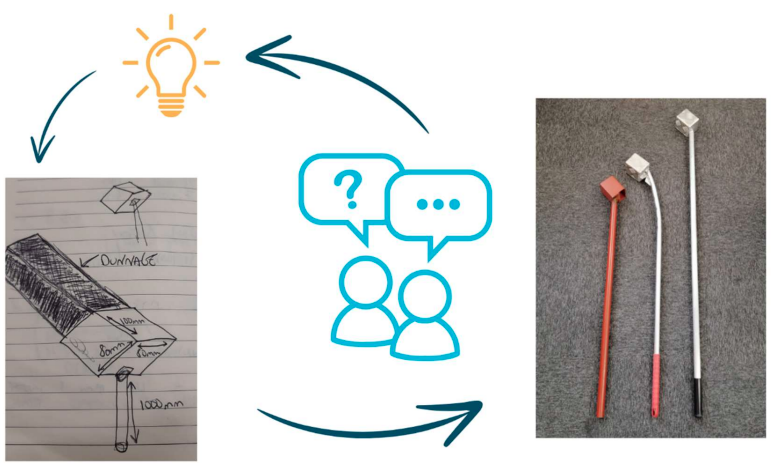

Key to the success of the project was the extent of engagement with port workers. As the ultimate users, their feedback throughout was invaluable. We worked with a local welding firm, converting a sketch into our first prototype. Our first model, made entirely from steel, was too heavy to be used comfortably. The second prototype was constructed from aluminium, which addressed the weight. More testing and feedback followed, subsequently our in-house workshop team adjusted the angle of the tool to ensure it was optimal for the task. After several trials, we commissioned the third protype, with a smaller angle, a longer pole and a thicker handle. The image below shows the evolution of the tool from first sketch to final design.

We then brought all the team together, to share the updated procedure for lorry loading, demonstrate the new tool, and to engage everyone in why we had placed so much energy and focus on this in the first place. Keeping health and safety relevant and engaging our colleagues in our mission to make the Port safer is of primary importance to us.

We measure both our leading and lagging safety indicators, a recent focus has been on making our leading indicators of ‘near misses’ and ‘safety observations’ easier to report for colleagues. The introduction of a simplified reporting system with a QR code has led to a 412% increase in reporting year to date compared with the same period in 2023. Despite this there have been no reports of accidents, near misses or safety observations related to the new process, confirming the new standards are embedding well operationally.

At Shoreham Port we take a risk-based approach to where our focus needs to be, and the increasing richness of our data means that we can continue to do to this effectively – our commitment to improving health and safety never stands still.

Engagement has been key to the success of the tool, we simply would not have been able to develop the design without the input of our colleagues on the ground. With use of the ‘dunnage placement tool’ embedded, we have shared the innovation with our Safety Improvement Team. This is a collective of colleagues from every area of the Port, that collaborate to uncover risks we might miss working departmentally, developing consistent solutions for pan organisational deployment.

This tool is the perfect example of a front-line innovation that has reduced our risk profile, enabling us to keep our colleagues safer, without reducing operational efficiency. We celebrate this innovation and hope to inspire more colleagues to create solutions, ideas and new ways of working.

We are keen to share this solution, which is not available on the open market. Any port that handles break bulk cargoes and currently places dunnage by hand, could make their operation safer by using the ‘dunnage placement tool’.

If our project were to be recognised as a finalist, presenting the ‘dunnage placement tool’ process at the Port Skills and Safety Members Conference would be an excellent opportunity for our Port Operatives to showcase their work. The event would provide a platform for us to demonstrate the ‘dunnage placement tool’ to the sector offering the opportunity for other members to adopt the process. To aid the dissemination of information across the sector we have produced a video which documents the process.

Debbie Cavaldoro – PSS | Martin West, Nicky Brown and Tom Rawlins – Shoreham Port

Stuart Wallace, Chair – PSS | Martin West, Tom Rawlins and Nicky Brown – Shoreham Port | Neil Dalus – TT Club, award sponsors.

Join Us

Find out more about the benefits of being a PSS member and how to apply.