Award Nomination:

AI solution safeguarding industrial workplaces:

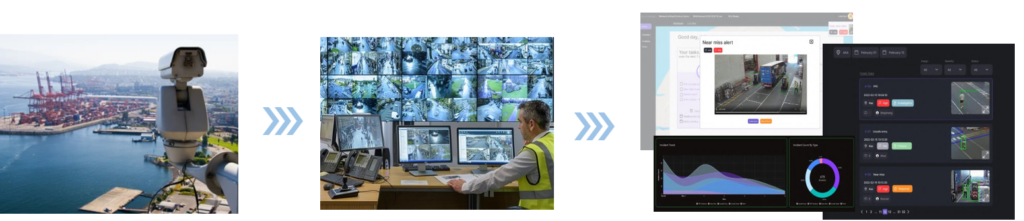

RoboK is at the forefront of safety innovation in the UK, transforming ports, railways and roadwork sites with its pioneering AI technology, SiteLens. Our solution seamlessly integrates with existing CCTV infrastructure to enable proactive hazard detection, thereby significantly enhancing safety across diverse industrial settings.

Strong market endorsement:

Our collaboration with the Bristol Port Company initially demonstrated SiteLens’s efficacy, achieving a remarkable 90% reduction in hazard detections within the first quarter of deployment. This compelling outcome highlighted our technology’s ability to mitigate risks and prevent accidents effectively. Encouraged by these results, other major UK ports including Port of Tyne, Port of Liverpool, and Port of Tilbury have since adopted SiteLens, leveraging its advanced analytics to safeguard their operations.

Empowering safety culture for all:

Expanding beyond port environments, SiteLens has proven equally effective in the rail and road sectors. Its deployment across these industries has not only led to safer workspaces, but has also empowered workers with enhanced situational awareness, contributing to overall workplace vigilance and safety culture.

By transforming passive surveillance into a dynamic, preventative tool, RoboK is setting new safety standards across the UK’s critical infrastructure. Our ongoing dedication to developing cutting-edge, impactful safety solutions makes us a strong contender for the Best Safety Moment award. This recognition would further validate our mission to make industrial workplaces safer for everyone involved.

Additional Information

The necessity for the RoboK SiteLens project stemmed from critical safety challenges faced by ports sector. The maritime industry, integral to the global economy, involves high-risk activities such as loading, unloading and transporting goods, where the interaction between workers and heavy machinery poses significant hazards, marked by frequent near-misses, unsafe working conditions and compliance failures, emphasizing the need for enhanced safety measures. The prevailing safety approaches, reliant on manual oversight and reactive strategies, are insufficient as they failed to pre-emptively identify and mitigate risks, as highlighted by HSE statistics on work-related injuries and fatalities, particularly within industrial work sites. Challenges with conventional approaches to safety implementation have limitations such as:

- Passive and reactive safety surveillance: Traditional approaches heavily rely on manual oversight and passive surveillance, often reacting to incidents/breaches rather than proactively implementing measures to prevent them.

- Lack of timely and structured information: Obtaining timely and structured information for managing large, dynamic logistics sites can be challenging and can lead to various safety failures.

- Manual approaches to situation-based safety training: In the absence of video data illustrating real-life safety scenarios, workers may not fully grasp the training, which can lead to an incomplete understanding of the risks involved and the necessary precautions to prevent accidents.

What Happened:

Recognising these challenges, RoboK developed the SiteLens system, an AI-driven technology designed to integrate with existing CCTV infrastructure within industrial settings. This system analyses real-time video data to identify potential hazards before they lead to accidents. The introduction of SiteLens aimed to transform passive surveillance into proactive safety management.

In its initial deployment at the Bristol Port Company, SiteLens was critical in addressing several long-standing safety issues:

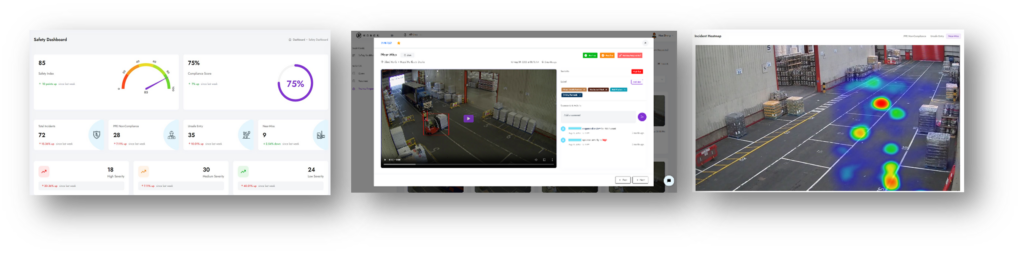

- Hazard detection: Leveraging AI, SiteLens continuously monitors the environment, detecting anomalies that could lead to safety incidents.

- Enhanced decision-making: The system provides actionable insights that enable immediate intervention, thus preventing potential accidents.

- Data-driven safety training: By capturing real-life safety scenarios, SiteLens facilitates more effective training sessions, helping workers understand and react to risks dynamically.

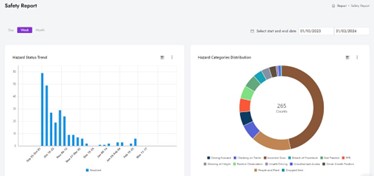

The success of SiteLens was measured through a combination of quantitative and qualitative metrics:

- Reduction in safety incidents: Within the first quarter of its implementation at Bristol Port, there was a 90% reduction in detected hazards, a direct indicator of the system’s effectiveness in enhancing workplace safety.

- Adoption across ports: Following the success at Bristol Port, other major ports such as Port of Tyne, Port of Liverpool, and Port of Tilbury adopted the technology, further validating its efficacy and adaptability.

- Feedback from workers and management: Improved safety culture and workforce engagement were noted, with workers expressing increased awareness and proactive involvement in safety measures.

- Industry recognition: The innovation and impact of SiteLens have been recognized in various safety and technology awards, reflecting its significance and acceptance within the industry.

The project’s necessity was underscored by the pressing need to improve safety standards while addressing the limitations of existing safety protocols. By providing a system that not only alerts but also learns and adapts, RoboK has set a new benchmark for safety in the maritime industry and other high-risk industrial sectors. This proactive approach to safety management via SiteLens has proven critical in transforming how safety is maintained at large, dynamic industrial sites.

RoboK’s unwavering commitment to enhancing industrial workplace safety, particularly within UK ports, is exemplified by its proactive approach to continuously developing and refining the features of SiteLens, its AI-driven safety system. Understanding that ports are dynamic and often hectic environments, RoboK is dedicated to adapting its technology to meet these evolving needs, ensuring that safety measures are not only robust but also agile enough to respond to the changing conditions of port operations. RoboK has also been able to secure a InnovateUK funded Trustworthy AI project with Port of Dover, Freeport East and the Bristol Port Company, focusing on building a proactive AI-powered solution for logistics efficiency, transparency and safety.

- Adaptation to Dynamic Environments: Ports are bustling hubs where operations and conditions can change rapidly. RoboK regularly updates the SiteLens system to handle these fluctuations effectively. This includes improving the system’s ability to detect and analyse a wider range of safety hazards that occur in busy port environments, from container movements to the coordination of heavy machinery and human activity.

- Enhancing Features Through Innovation: RoboK invests significantly in research and development, drawing on the latest advancements in AI and machine learning. This commitment ensures that SiteLens stays ahead of potential safety challenges by integrating cutting-edge technologies that enhance its predictive capabilities. These innovations allow SiteLens to not just react to immediate risks but also forecast potential future hazards, thereby preventing accidents before they happen.

- Stakeholder Collaboration: RoboK actively engages with port operators, workers, and safety officials to gather insights and feedback on the effectiveness of SiteLens. This ongoing dialogue helps RoboK to tailor its technology to better suit the specific needs of each port, ensuring that the system is both effective and user-friendly. This collaborative approach also aids in embedding a proactive safety culture within the ports, making safety a shared priority among all stakeholders.

- Training and Empowerment: Recognising that technology alone is not enough, RoboK provides comprehensive training programs for port workers and safety personnel. These programs are designed to maximise the benefits of SiteLens by ensuring that all users are proficient in using the system and can fully leverage its capabilities to maintain safety. Training sessions are regularly updated to reflect new features and functionalities, empowering workers with the knowledge to handle both current and emerging safety challenges.

Through these efforts, RoboK demonstrates its commitment to maintaining the highest standards of safety in UK ports. By continuously enhancing SiteLens and fostering a collaborative, informed safety culture, RoboK is setting new benchmarks for safety in industrial workplaces, ensuring that they are safe, efficient, and adaptable to the demands of modern maritime operations.

Join Us

Find out more about the benefits of being a PSS member and how to apply.